While interning at 3D Systems’ R&D Material Testing Lab, I had the opportunity to familiarize myself with a variety of material testing tools and procedures. I performed static & dynamic load testing and impact testing & analysis on existing equipment and also got to design custom material testing components and platforms.

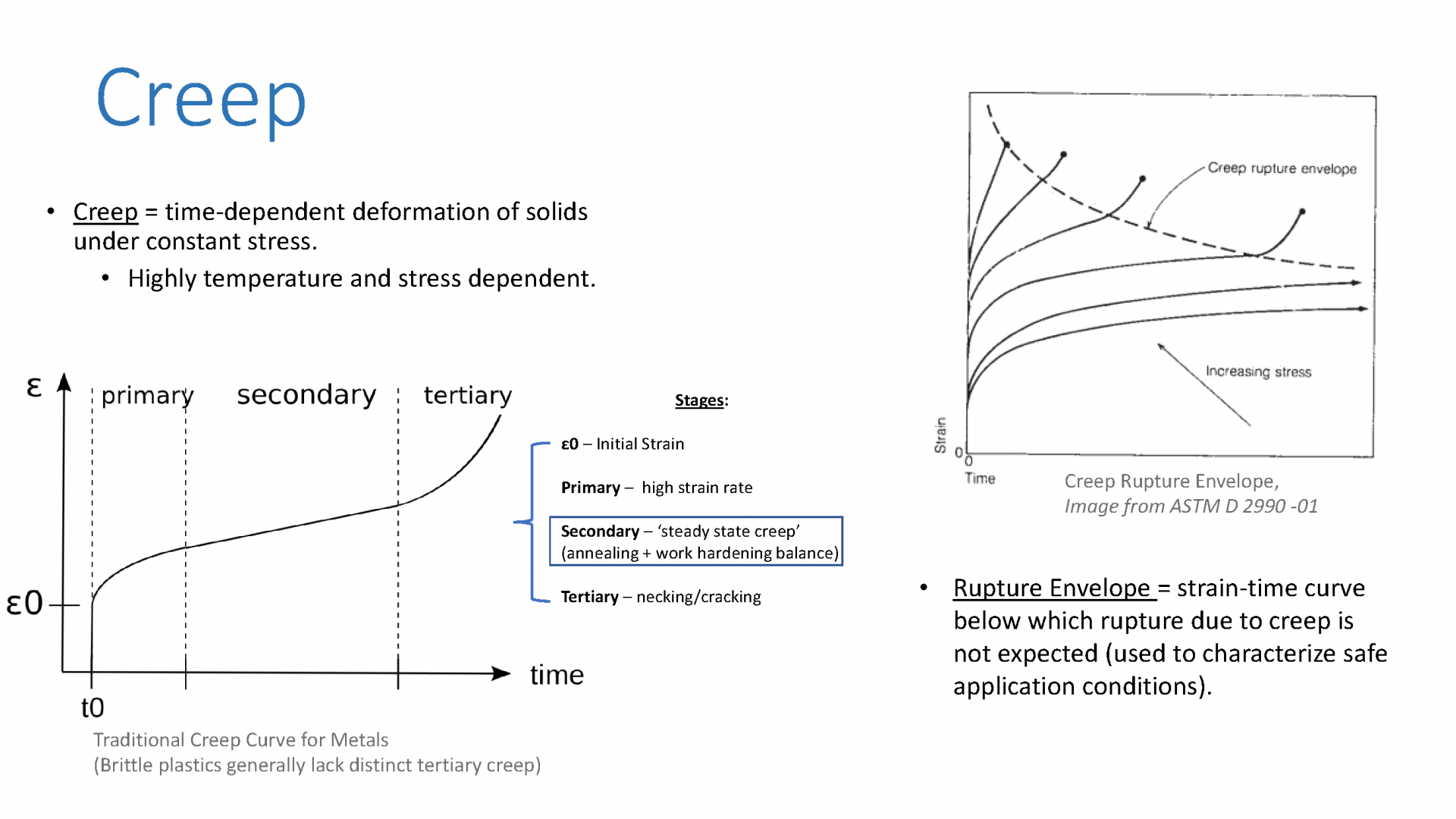

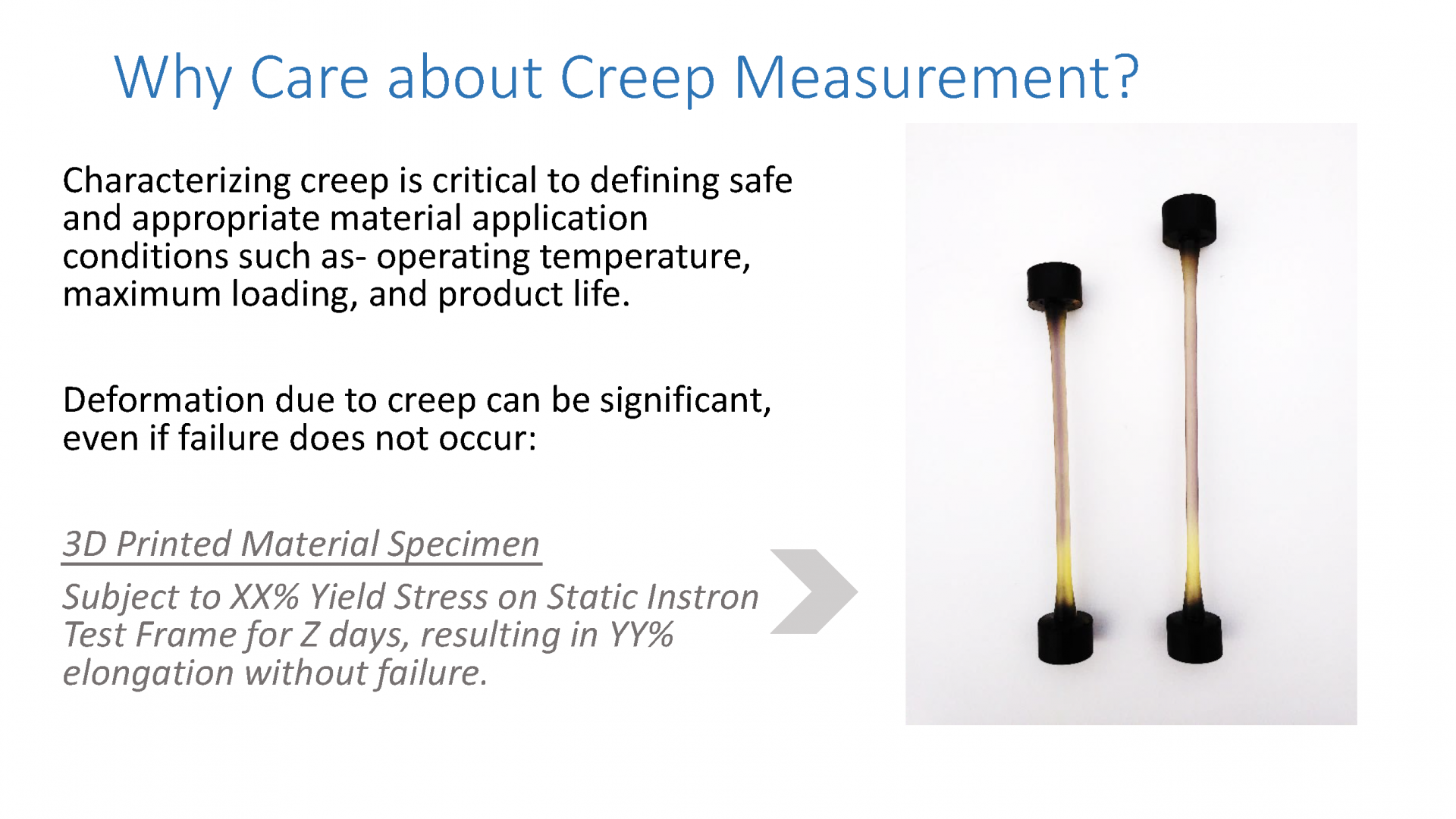

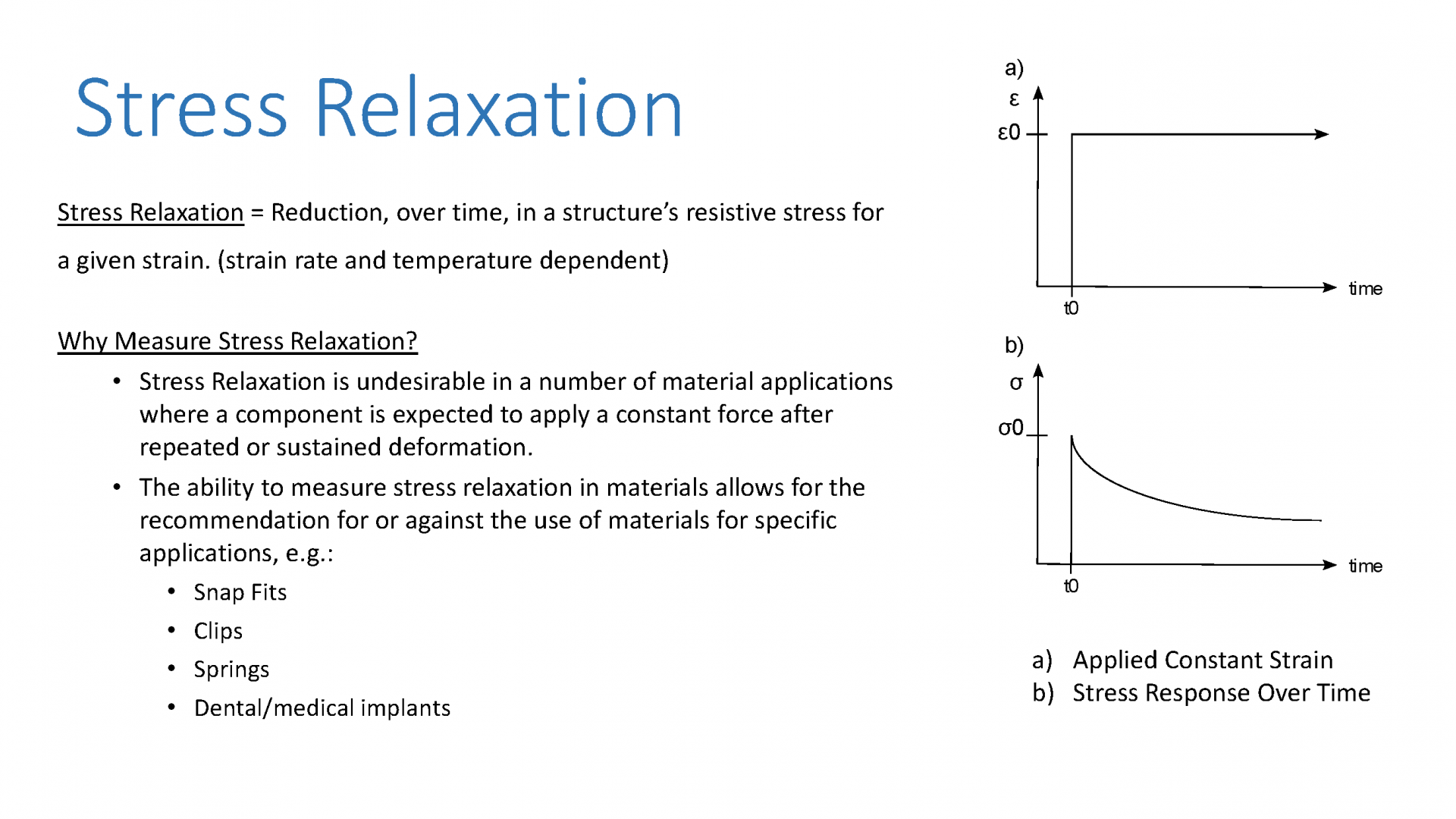

3D printed materials have unique properties that must be characterized to determine safe and appropriate application conditions and lifespans. Due to their deformable nature, many traditional testing tools designed for metal samples fail to appropriately capture the failure modes of plastics.

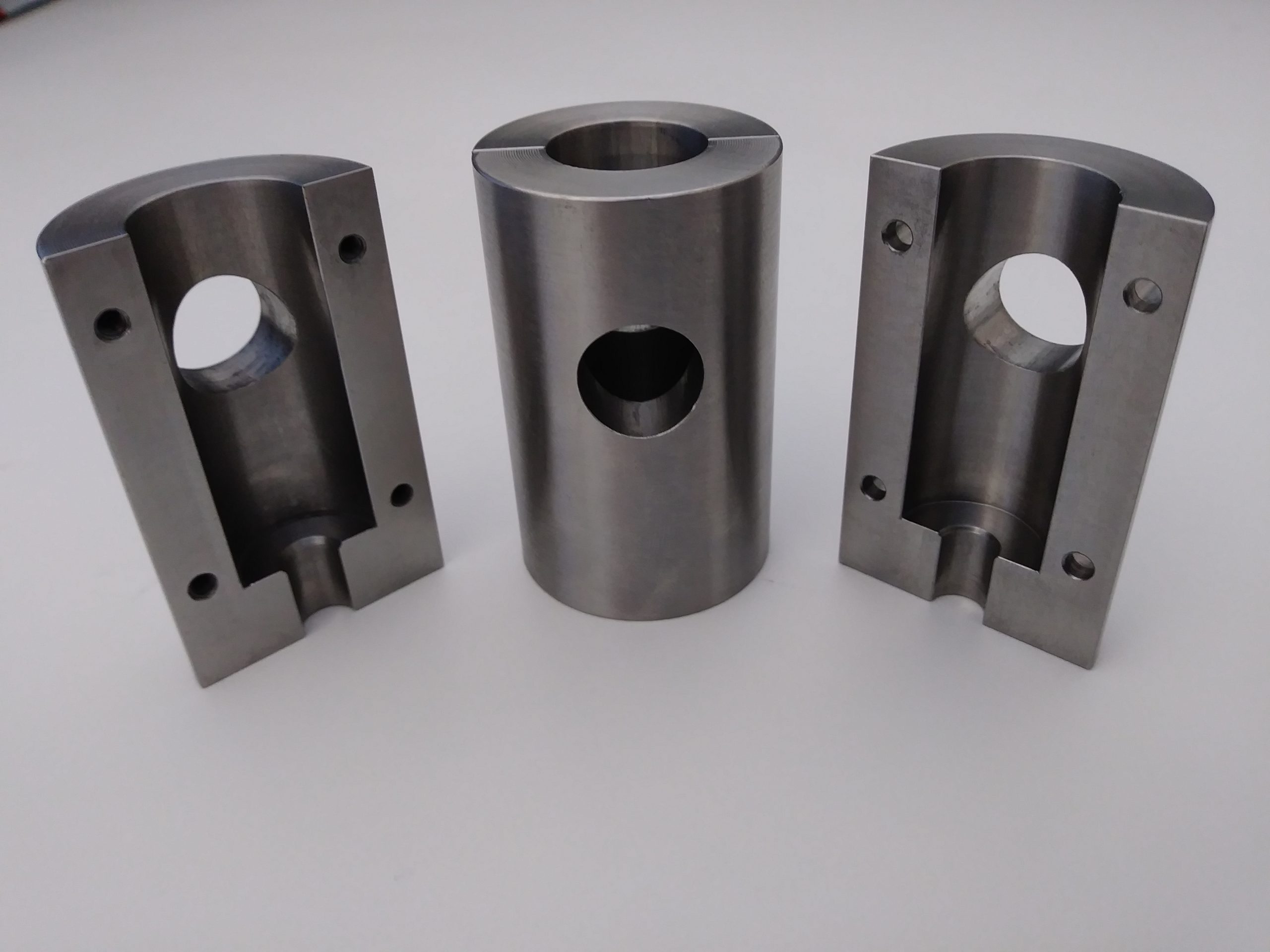

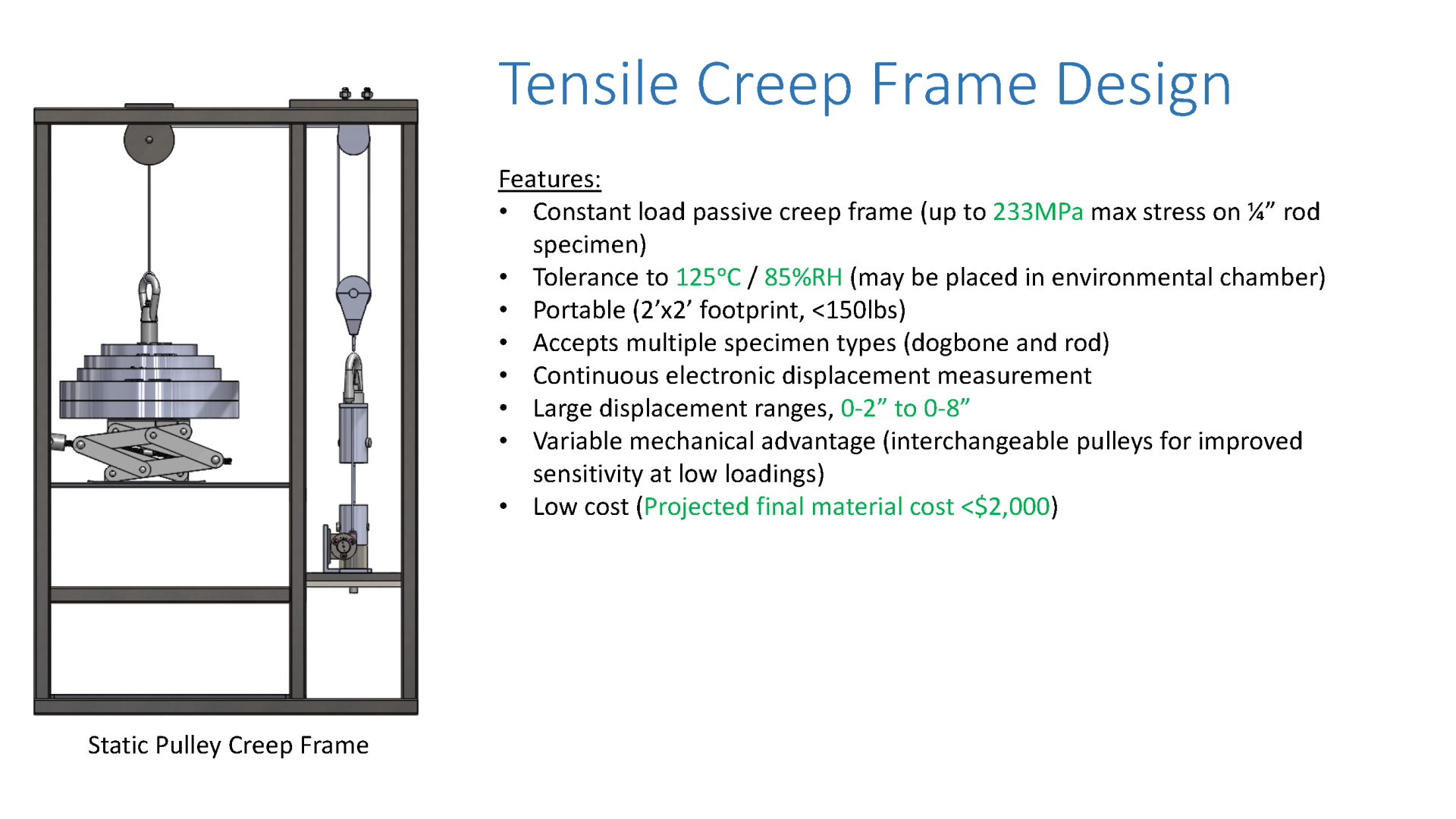

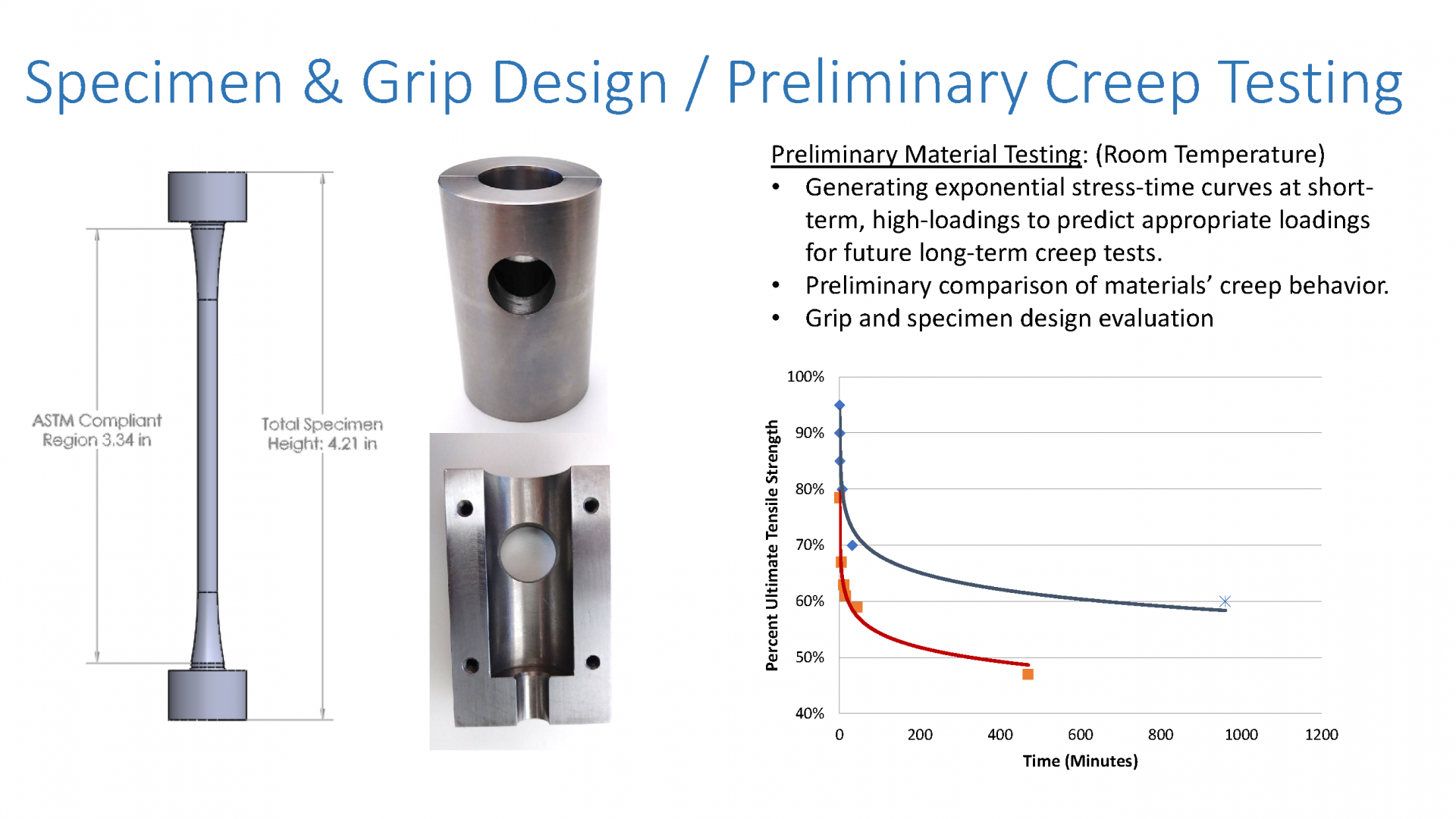

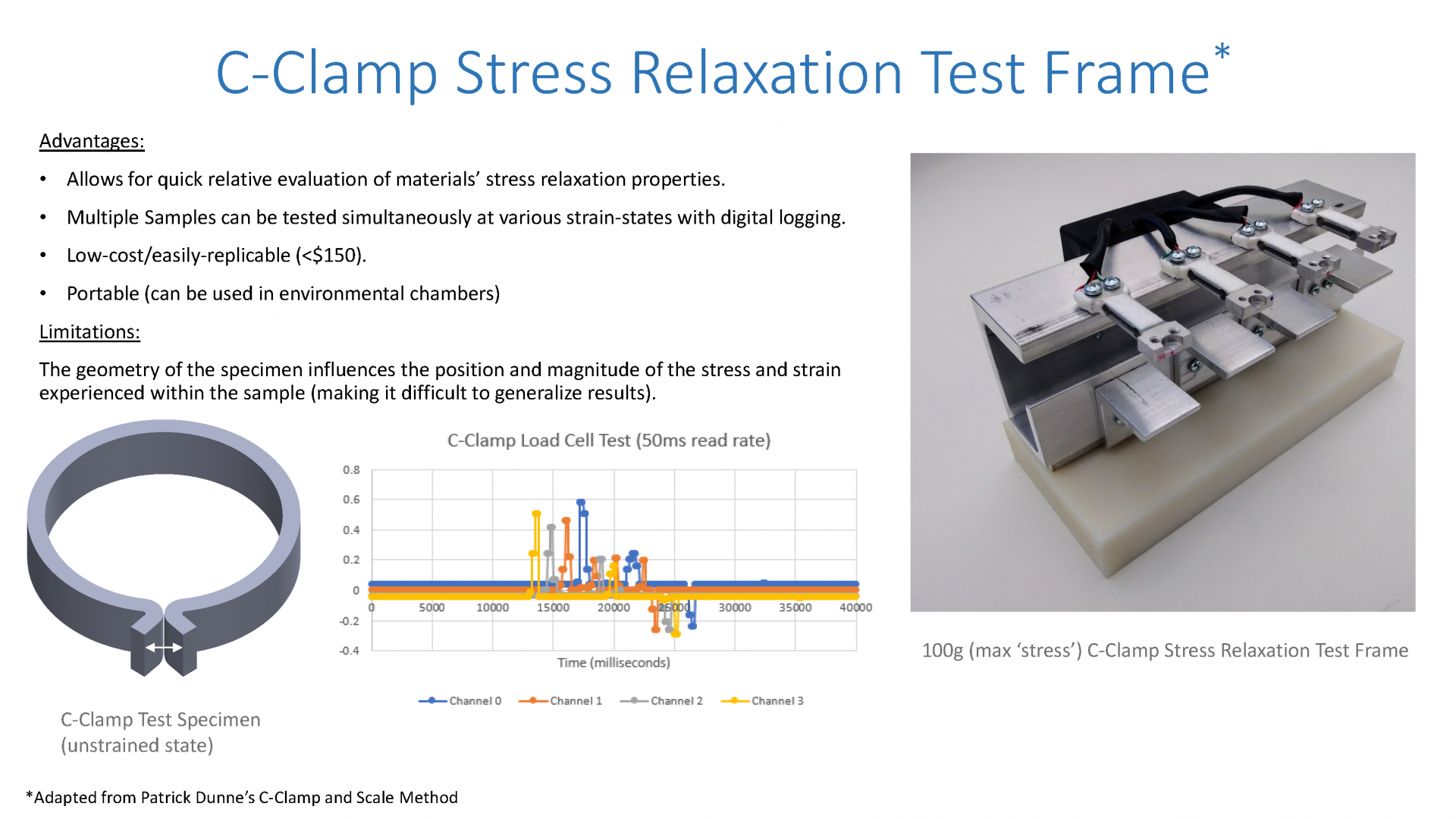

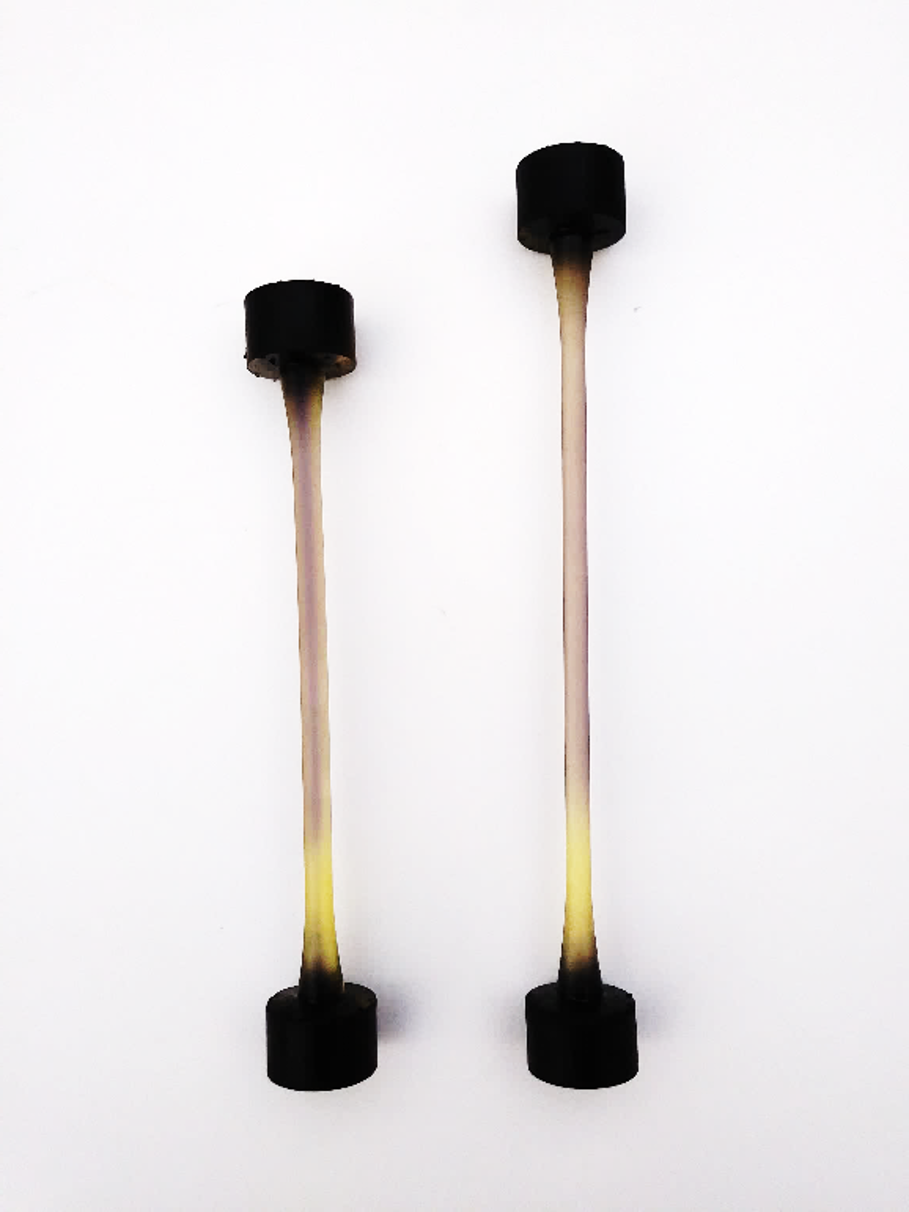

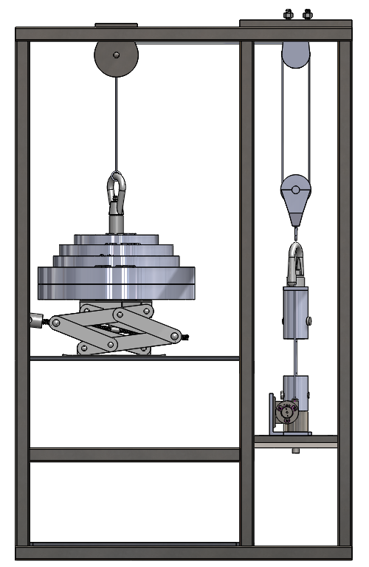

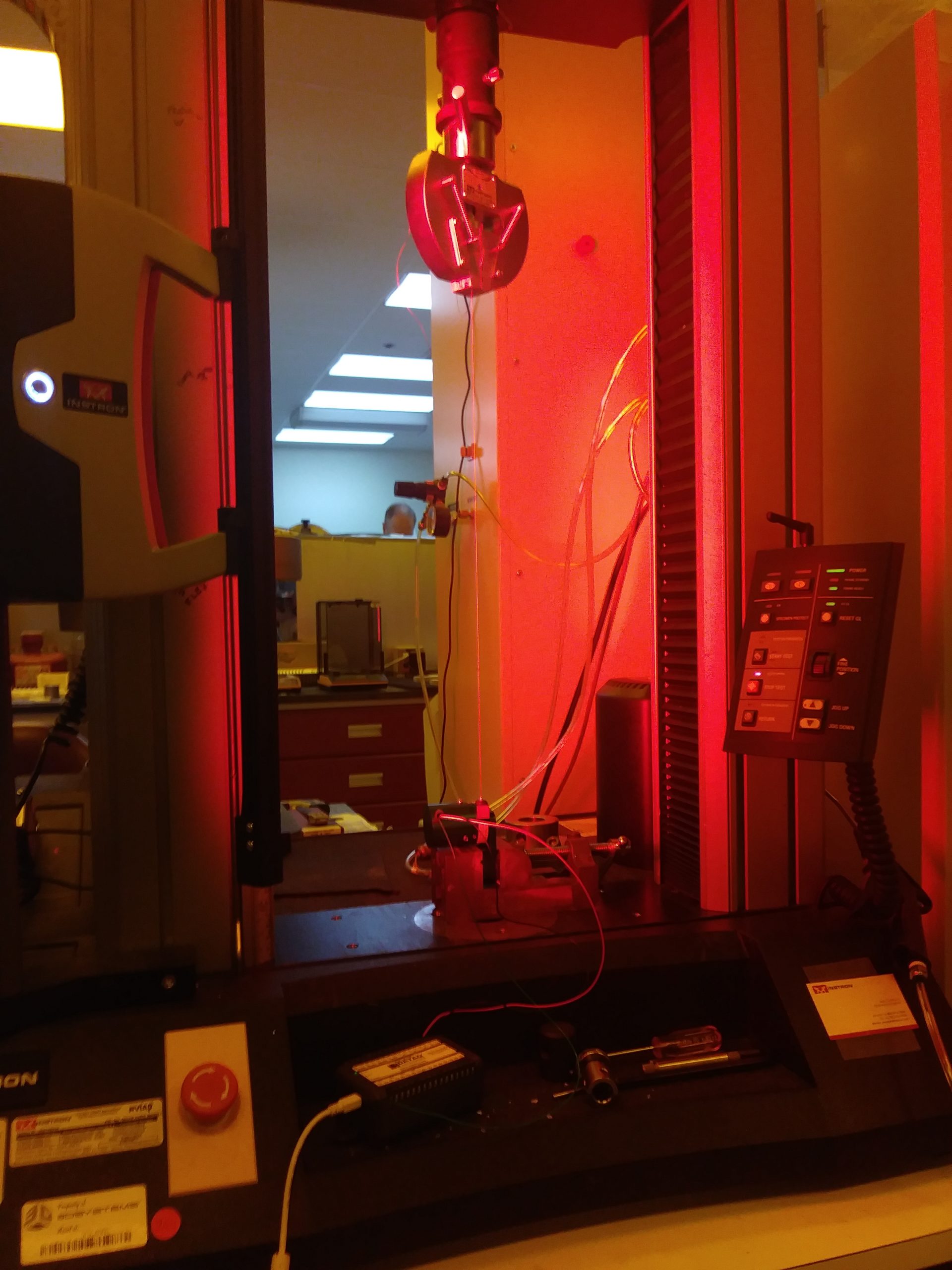

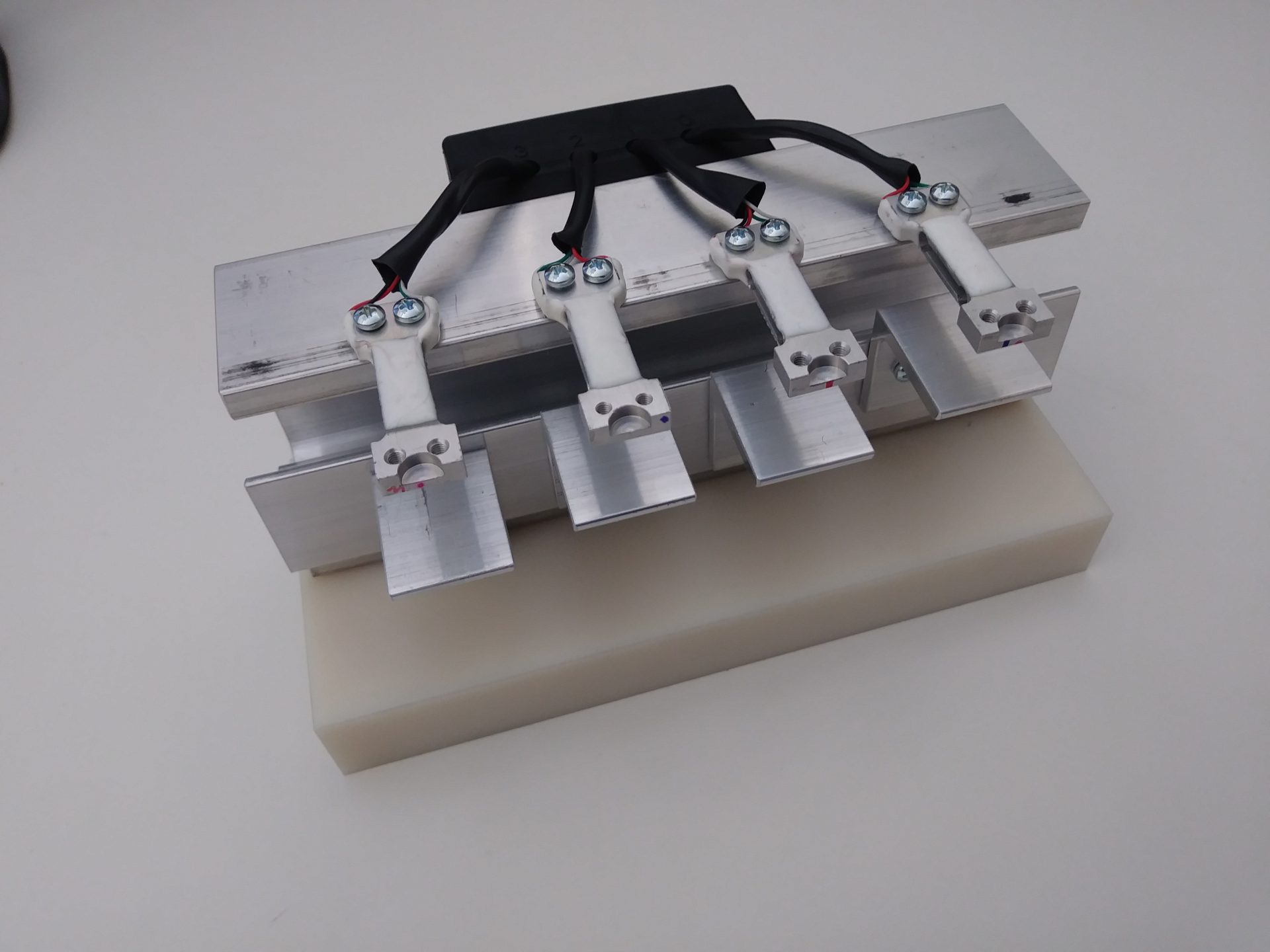

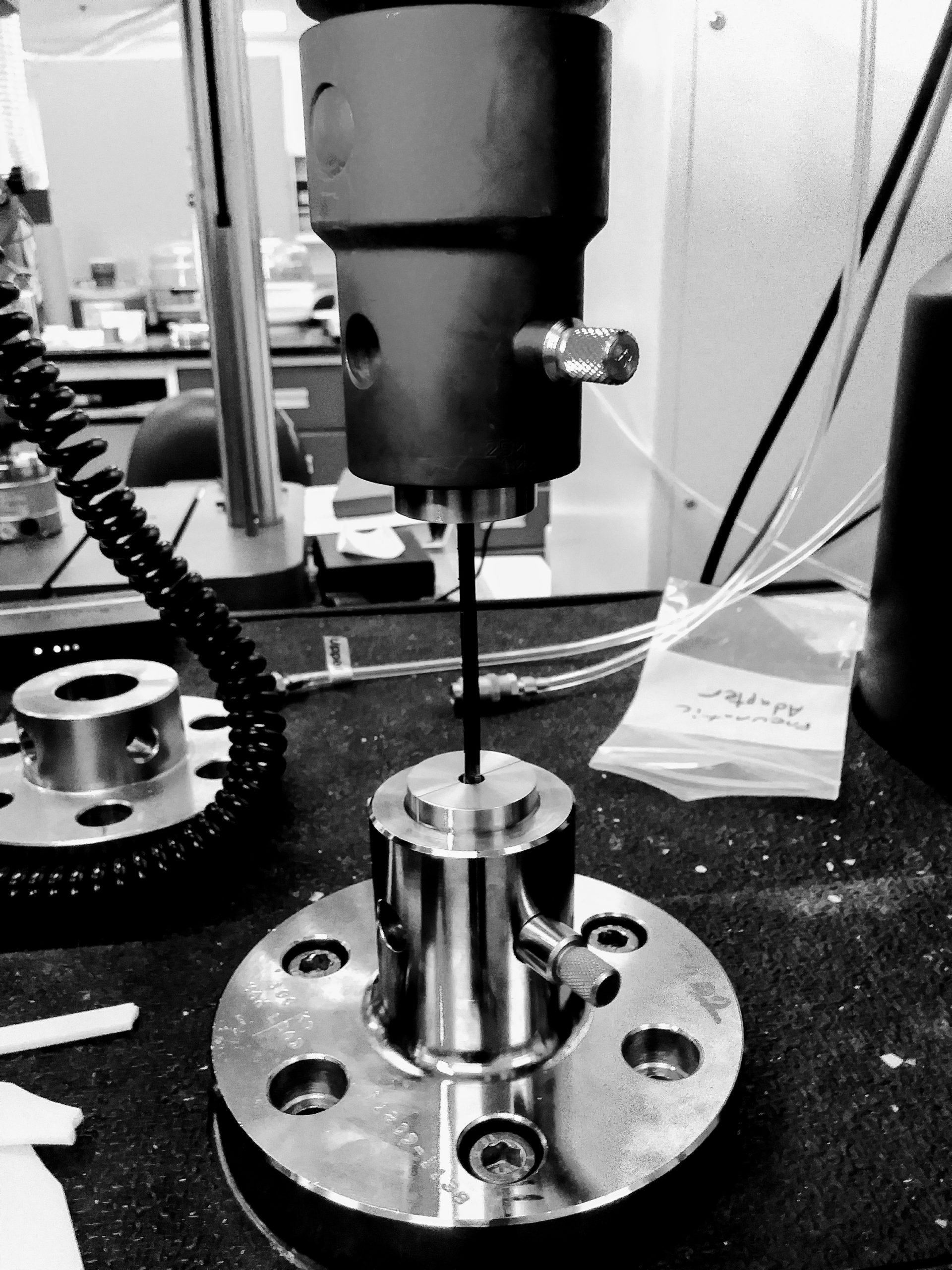

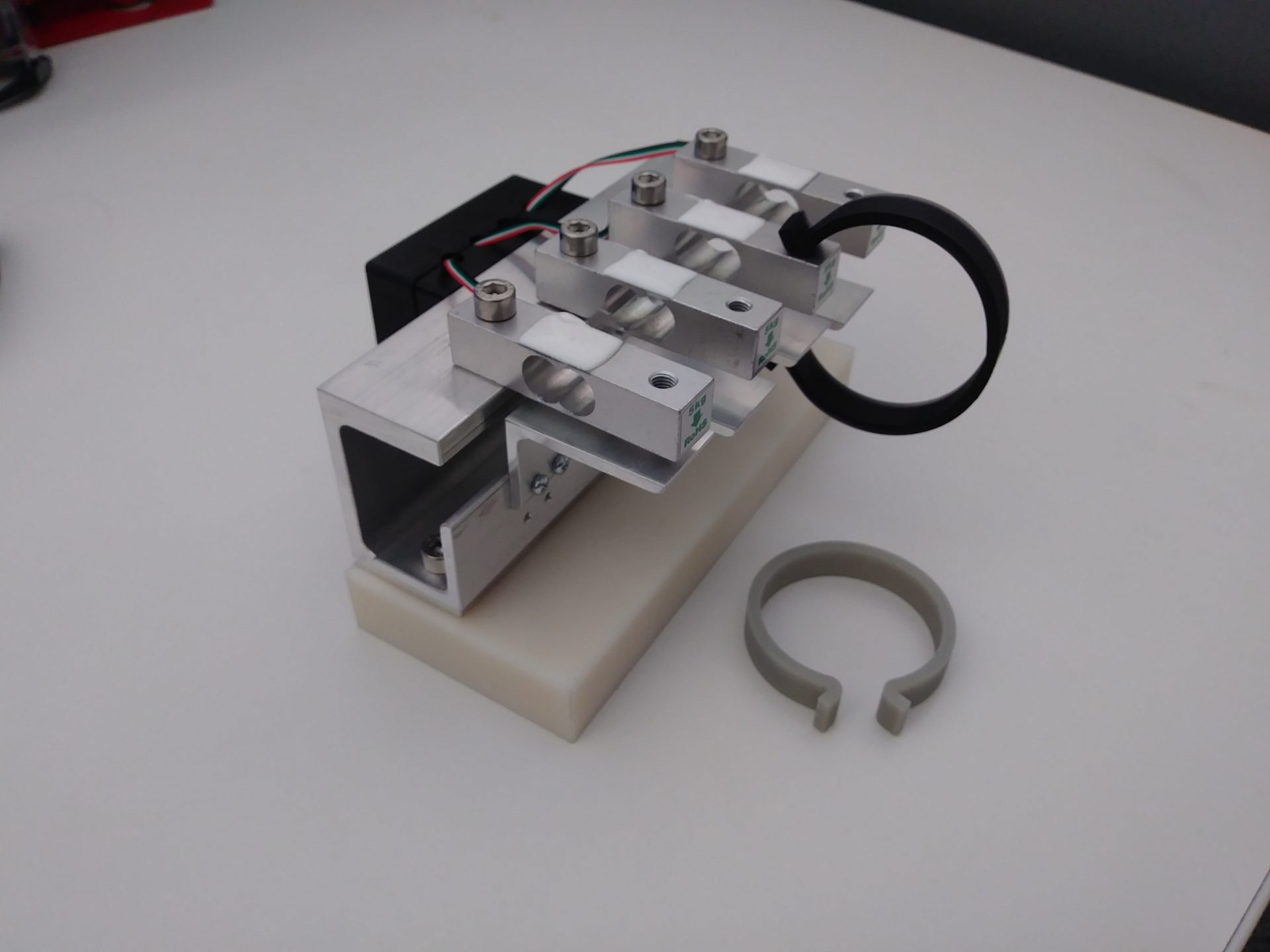

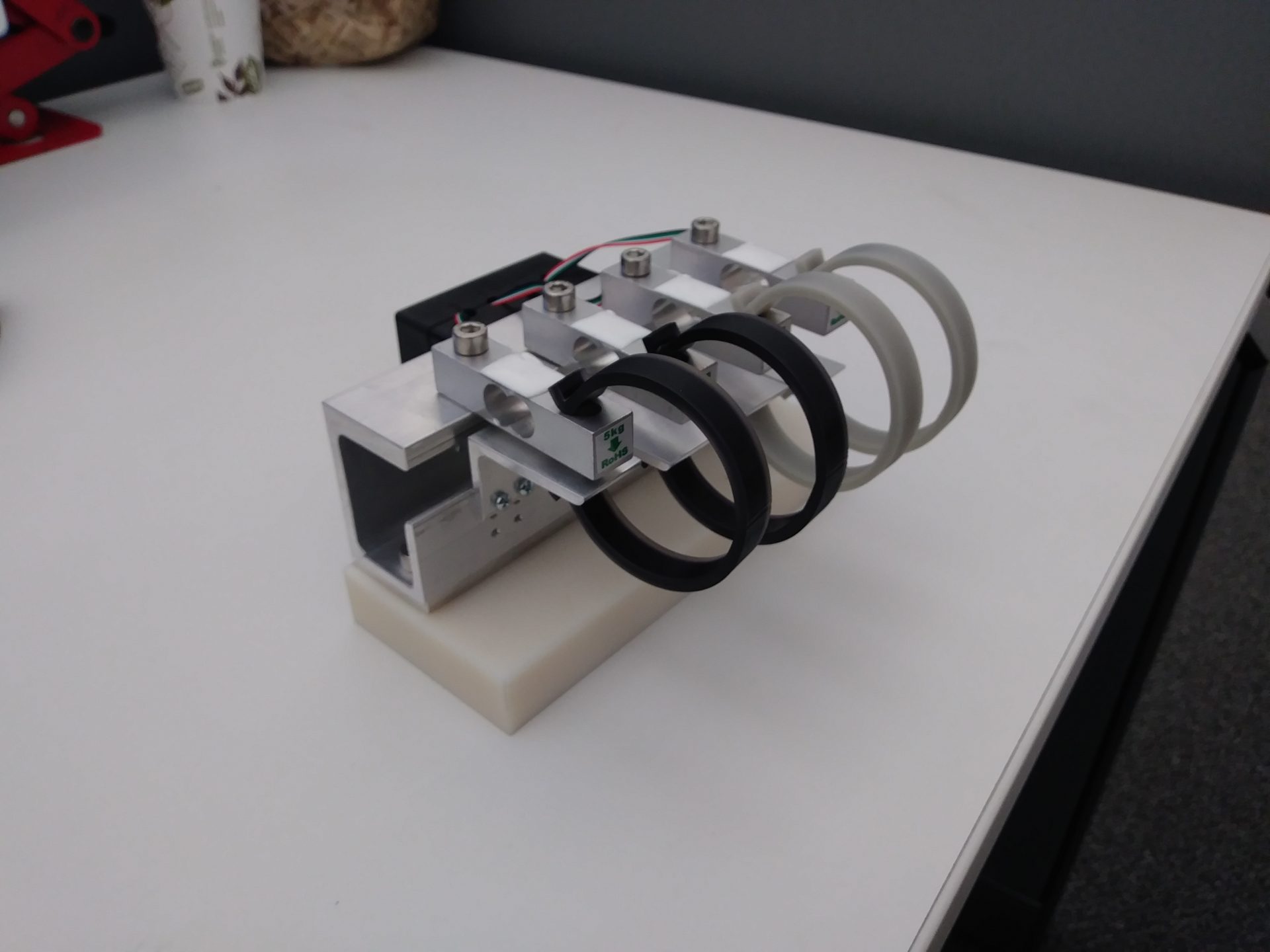

I designed a custom sample geometry and test grips for evaluating tensile strength & strain behavior, based as closely as possible on existing ASTM standards as well as deformation-tolerant passive creep & stress relaxation test frames. Due to NDA (it was an R&D lab), I won’t be posting too many details, but please enjoy some photos!

I also got to print some things in 3D System’s CJP printer – a form of powderjet printing technology that includes full-spectrum color printing. I usually only use Solidworks for engineering models, but I figured I should do something a bit more fun, to take advantage of this color feature. So, I tried my hand at something a bit more organic…

Here is my best attempt at Homer Simpson – I also made him wearing a friend’s band t-shirt. I didn’t expect the detail to come through on that scale, but I was impressed!