A custom, friction-fit furniture set – which disassembles into flat, stack-able pieces for compact storage.

This Project was developed for PCC Cascade’s Paragon Art Gallery, which required a full furniture set for a single exhibit.

The criteria for the furniture was that it:

- include 12 stools, 2 large tables, and 1 coffee table.

- be made out of 1/2” plywood

- be easily dis/assemblable for compact storage and repeated use

- complement the aesthetic of the exhibit artist

The tools used for this project were Fusion 360 for design and a Shopbot DesktopMax CNC Router for Fabrication (courtesy of PCC’s Cascade Fab Lab).

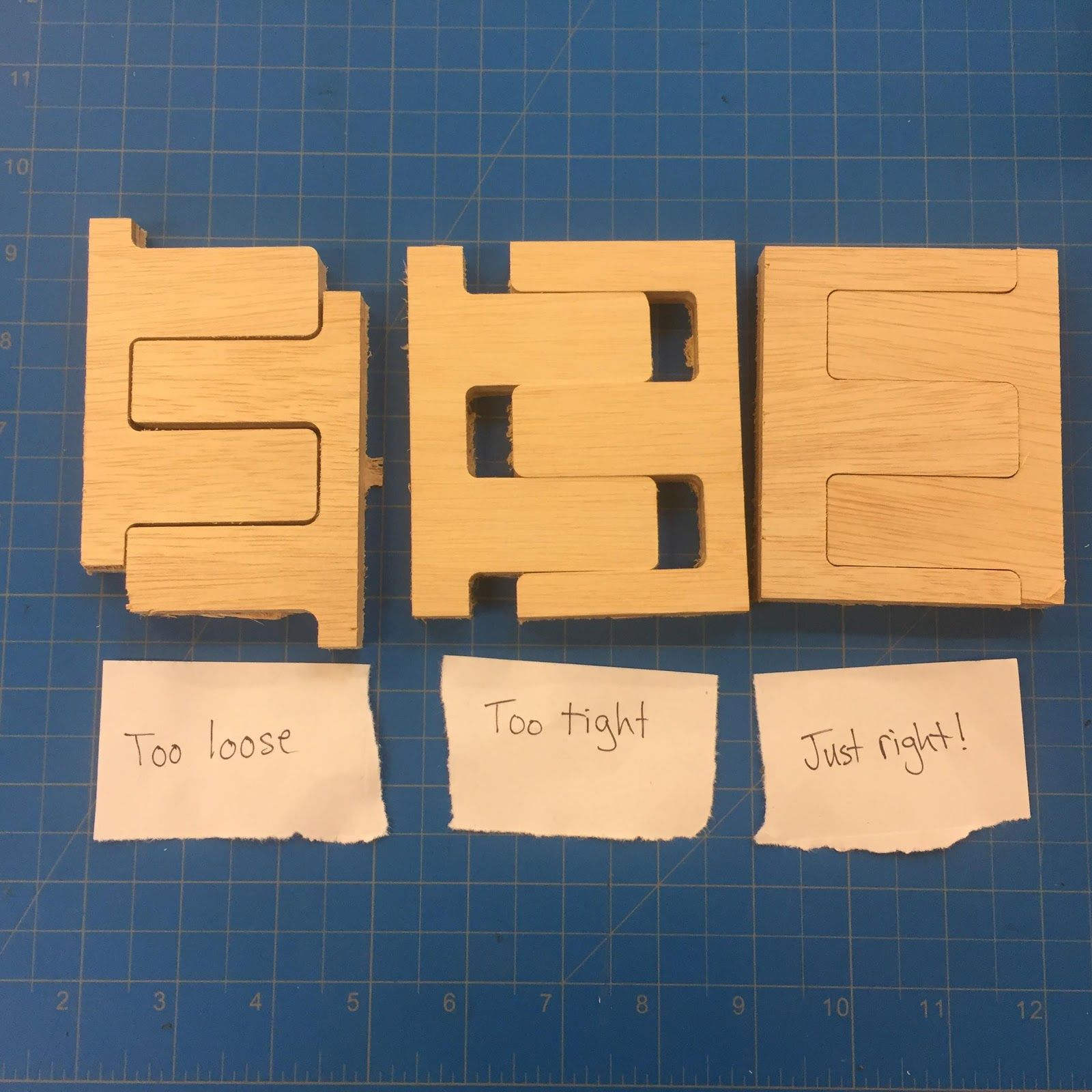

It took a bit of experimentation to determine the ideal slot dimensions to achieve a friction fit that held the pieces together, without being permanent. The best solution was to make the top slots tighter than the bottom slots, so they fit tightly but the force required to separate them was less.

Full-length tables were achieved by inserting wood 1/2 way into CNC, then routing one end at a time, or in the case of the coffee table, routing two pieces designed to friction-fit together using the interlocking pattern seen above.

2D Design Files are not provided as dimensions and kerf values for friction fitting will vary depending on the machine and material properties. 3D design files are provided for reference, but would need to be tweaked to match desired material and scale. The design is fairly simple, and part dimensions were largely determined by the maximum machinable area of the CNC router bed (2’x3′).

Special thanks to Darcy Neal, PCC STEAM Coordinator, for helping with the final production run, ensuring all 12 stools were complete in time for the exhibit.